Spectacular Metalenses: How They Work and the Applications They Enable

Metalenses are the future of optics. They are thin, lightweight, and can be fabricated using a variety of materials. What’s more, they can be used to create lenses with very different properties than those found in traditional lenses. In this blog post, we will discuss how metalenses work and some of the exciting applications that they enable!

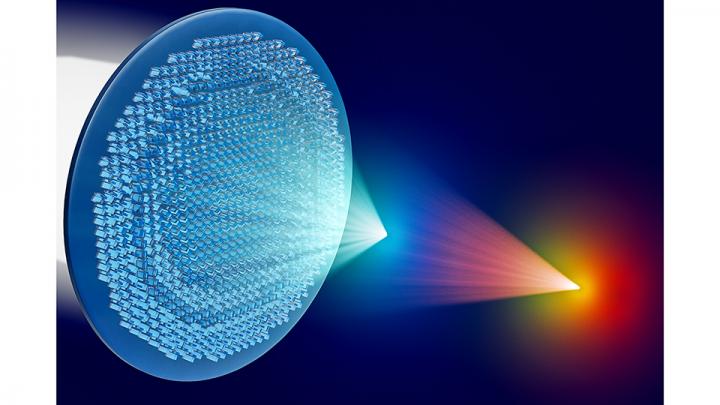

Traditional lenses are made of materials like glass or plastic. These materials have a refractive index, which determines how light bends as it passes through the lens. Metalenses are made of nanostructured metals, which do not have a refractive index. Instead, they rely on the way that light interacts with their surface to focus it.

One of the benefits of this is that metalenses can be much thinner than traditional lenses. They also don’t suffer from chromatic aberration, which is when different colors of light are focused at different points. This results in images that are clear and free from distortion.

One potential application for multifocal lensing is augmented reality (AR). AR devices like the HoloLens use multiple lenses to focus light in different directions, which allows them to create the illusion of three-dimensional objects. Metalenses could be used to create even more realistic AR experiences by providing more focal points.

How to Implement Metalenses

Now that we’ve seen some of the potential applications for metalenses, let’s take a look at how they can be implemented. There are two main ways to create metalenses: top-down fabrication and bottom-up assembly.

Top-down fabrication is the process of creating metalenses from larger pieces of material. This can be done using traditional machining methods like milling or etching. However, it can also be done using newer techniques like extreme ultraviolet lithography (EUVL). EUVL is a form of lithography that uses high-energy ultraviolet light to pattern materials at the nanoscale.

Bottom-up assembly is the process of creating metalenses by assembling smaller building blocks. This usually involves creating nanostructures from materials like metals, semiconductors, or dielectrics. These building blocks are then arranged into the desired lens shape and held in place with some type of adhesive.

Bottom-up assembly offers a few advantages over top-down fabrication. First, it allows for more complex lens shapes to be created. Second, it’s generally less expensive and easier to scale up. However, bottom-up assembly is still a relatively new technology, so it will likely take some time before it can be used to create metalenses on a large scale.

Conclusion:

Metalenses are a new type of lens that has the potential to revolutionize optics. They are thinner than traditional lenses, don’t suffer from chromatic aberration, and can be fabricated using a variety of methods.

Metalenses also have some unique properties that make them ideal for certain applications, like augmented reality and medical imaging. While metalenses are still in the early stages of development, they have the potential to greatly improve the performance of optical devices.